Junior Engineering Bootcamp

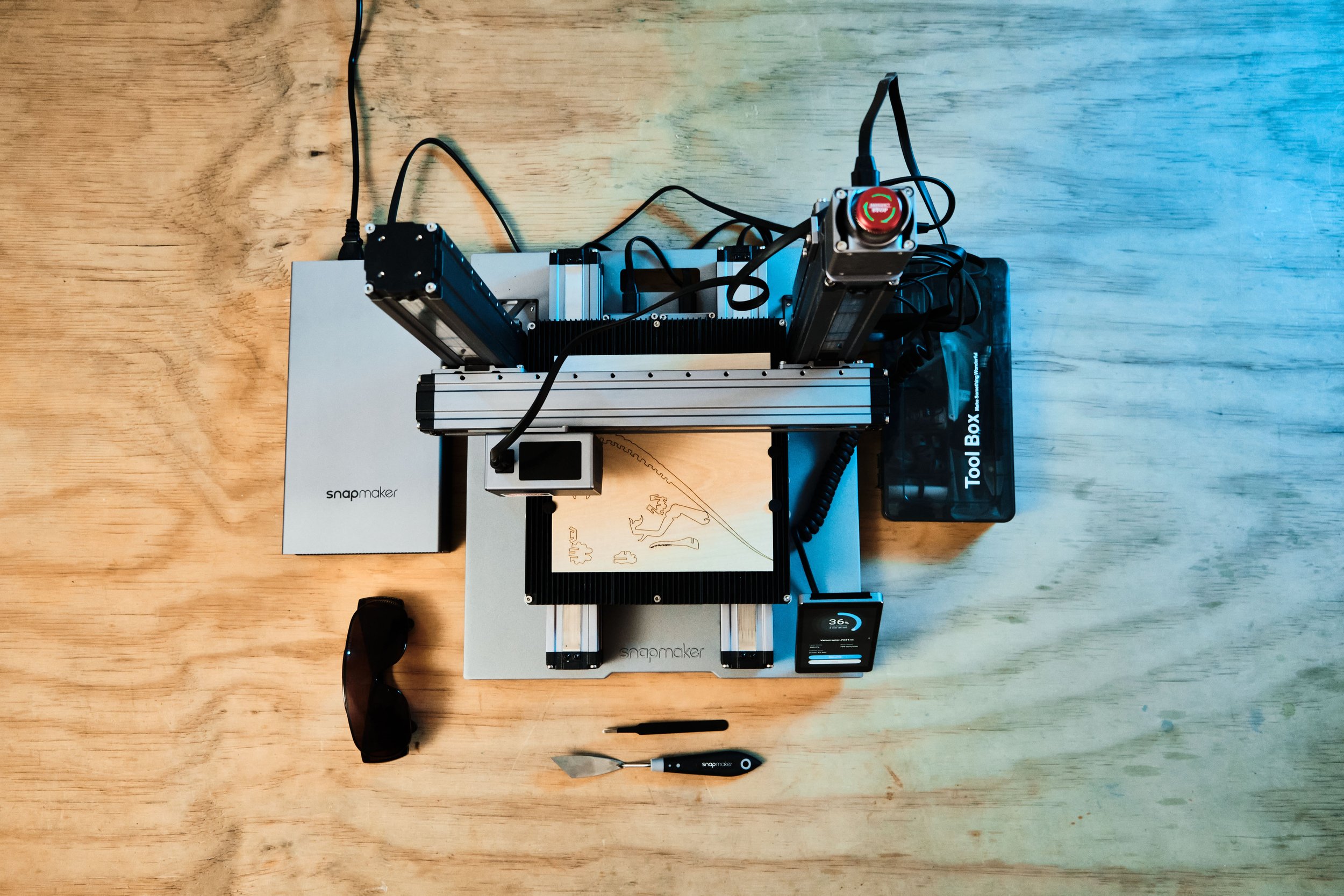

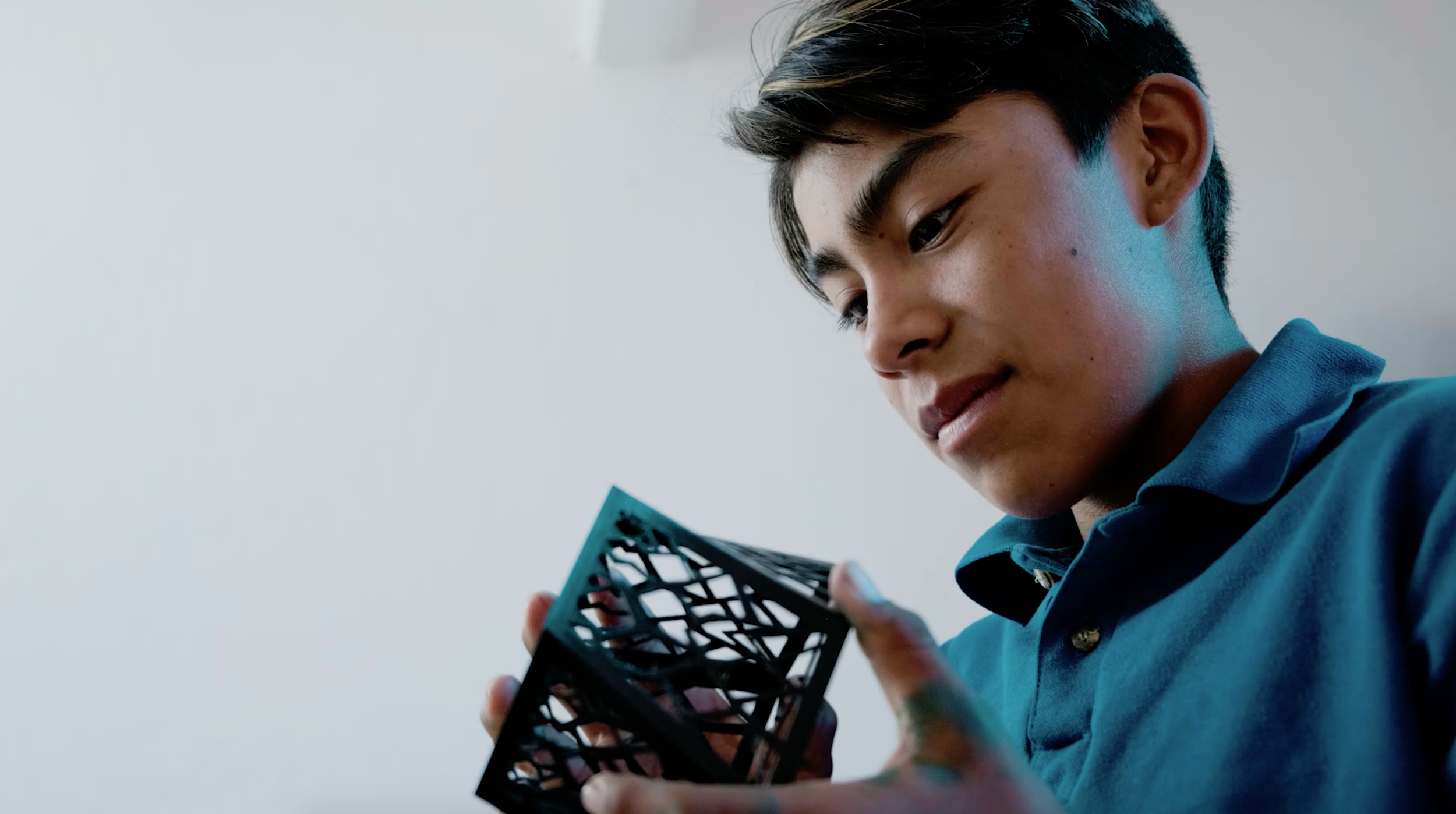

Learn to make 3D designs with Fusion 360 and then bring them to life on a SnapMaker™ 3-in-1 prototyping machine.

You get your very own SnapMaker and 10 days of in-person instruction on how to use it and Fusion 360 to design whatever you can imagine!

Who’s it for?

Any students ages 12+. No previous engineering knowledge necessary.

Whether you feel drawn to engineering, just enjoy making cool things, or want your college application to stand out, you'll love the Junior Engineering Bootcamp! You can even make your skills official with an AutoDesk Certification Exam.

-

Fusion 360 is a versatile engineering package. With it, you can design any 3D model you can imagine, create professional-grade renders, perform stress-test simulations, and export the design to a 3D printer, laser cutter or CNC computer-controlled router.

-

The SnapMaker™ features all three of these capabilities, plus a user-friendly interface. Use its 3D printer to create any object out of plastic. Cut shapes and etch images with its laser. Or carve your designs with its 3-axis CNC router. And gain extra versatility with the rotary spindle, enabling you to carve and etch in 360!

-

The Bootcamp runs for ten days, three hours a day, in the convenience of your home. You get your very own SnapMaker™ 2.0 A350T, training on how to use it, and extensive instruction in Fusion 360, with an extensive library of exercises, project ideas and more. Check now for availability between June and August, 2023.

CNC

CNC machining uses a milling bit (similar to a drill bit) to carve away, layer by layer, from a block of material, leaving your finished design. Normally, a 3-axis CNC can't carve up underneath, because the bit only comes down from above. But with a rotary axis, which can rotate the material, the possibilities are greatly expanded!

Laser

Laser cutting is exactly what it sounds like, and can create very cool designs and patterns. But by cranking the power down and the speed up, the laser merely burns the surface of the material. This allows text and images to be etched onto wood, acrylic plastic, leather... You can even etch onto a cylinder by using the rotary axis!

3D Printer

3D printing lays down a filament of melted plastic, zig-zagging to create a 2D shape. It then lays down another layer on top of that, and another atop that, and so on, changing each layer every so slightly to create your 3D form.

What’s included:

SnapMaker™ 3-in-1

We will be learning on the machine that you get to call your own.

Fusion 360

After our program ends, you’ll have continued access to keep designing your prototypes.

Materials

You will have access to raw materials such as balsa wood, MDF, acrylic sheets and any other materials that you may need for your design.

Teacher

3 hours of private in-person teaching daily with Milan Kidd for 10 days (weekends optional).